How to: Verify the Motor Arm Angle

Calibration Process of the Arm Angle of the P Series Agricultural UAV in 2024

I. Introduction

For the P series agricultural drones in 2024, angle calibration is required during the process of replacing the drone arms. Failure to operate in accordance with this procedure may result in the maintenance effect failing to meet expectations or the emergence of secondary risks. Please read carefully and implement strictly in accordance with the procedure.

II. Scope of Response

- Overseas

III. Classification

- P series agricultural unmanned aerial vehicles of the 2024 model

IV. Maintenance tool

- Digital pitchometer

V. Maintenance tool

- Xcare tool

VI. Mobile operating systems

- Android

- HarmonyOS

Arm Measurement and Replacement Procedure

I. Measurement Steps for the Fuselage and Drone Arms

- Overall Inspection

Fuselage side

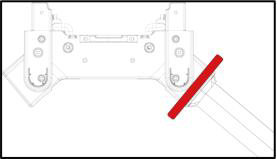

Turn on the digital pitchometer, invert it and place it horizontally so that it is perpendicular to the side beam. Ensure that the angle of the screen is perpendicular to the direction of the drone arm, and then record the current angle value(α)

Placement position at the fuselage side

Motor side

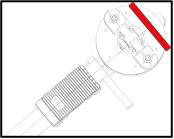

Invert the digital pitchometer and place it vertically on the upper surface of the motor. Make sure that the angle of the screen is perpendicular to the direction of the drone arm and then record the current angle value (β).

Placement position at the motor side

II. Methods for Verifying the Angle Difference

Subtract the angle at the root position of the drone arm on the main frame from the angle at the motor position to obtain the result of the angle difference.

Calculation formula

Δθ=∣α−β∣

α: Main frame arm root position angle

Β: Motor position angle

Δθ: Angle difference

Example:

α | β | Δθ | Qualification Status |

10 | 10 | 0 | Y |

0 | 0.6 | 0.6 | N |

0.5 | -0.5 | 1 | N |

0.1 | 0.5 | 0.4 | Y |

Cautions:

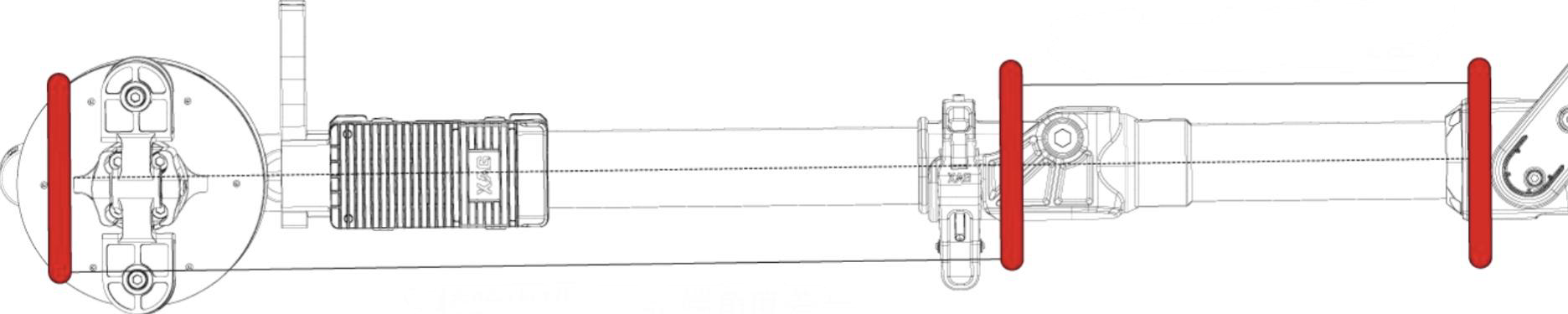

The angle difference shall not be greater than 0.5°. When it is greater than 0.5°, a secondary measurement is required to check the structural conditions of the motor and the drone arm. For the secondary measurement, it is necessary to check the angle difference between the folded part of the drone arm, the fuselage, and the motor end, and replace the parts with a relatively large angle difference.

After the replacement is completed, the overall angle difference needs to be re-measured, and adjustments should be made in a timely manner until the measured data does not exceed 0.5°.

Verify angle difference between middle section and fuselage

Verify angle difference between middle section and motor end

Assembly Requirements for the Drone Arm at the Fuselage End:

Location of Key Measurement and Control Point: The fixing bolt of the drone arm

Tool for Key Measurement and Control Point: Torque wrench

Torque at Key Measurement and Control Point: 29-31Kgf.cm

III. Hovering Inspection

After confirming that the angle of the drone arm is correct and the installation is completed,

the Xcare tool should be used for an outdoor test to confirm that the equipment is operating

normally without any abnormal jitter.