With the increase in the number of acres of unmanned aircraft operations, the items that require maintenance will gradually increase. Everyone should carry out maintenance in these four stages, which are 3,5 mu, 1,<> mu, and <>,<> mu after each operation. Below we will introduce the maintenance items at each stage in turn.

Stage 1: Maintenance items at the end of each operation

1. Clean the body and medicine box

Maintaining the medicine box can make the medicine box pipeline not easy to wear and corrode the medicine box pipeline, so how to maintain the spray system, you can check and maintain the following parts.

The first step is to open the "XAG Agricultural Service 4.0" App, enter the spraying system, click "Manual Spray Test", and empty the remaining liquid in the medicine tank and pipeline;

In the second step, fill soapy water or soap powder water, neutralize the residual pesticides, and empty again;

In the third step, pour clean water into the medicine box, click "Manual Spray Test", and empty the medicine box and pipeline;

In the fourth step, use a high-pressure water gun to rinse the fuselage to ensure that it is clean and stain-free, and dry the unmanned aircraft.

2. Clean and inspect the power system

Maintenance of propeller is to make the propeller can play the best efficiency in the daily operation process, reduce the vibration of the body, indirectly protect other parts of the body, and can check and maintain the following parts.

The first step is to check the blades of the propeller, if there are cracks or defects, the blades need to be replaced; If the paddle blades shake up and down, tighten the screws or replace the damaged paddle clips and paddle cards;

The second step is to check the ESC surface, if there is any adhesion, use a soft brush to brush the surface liquid and stains;

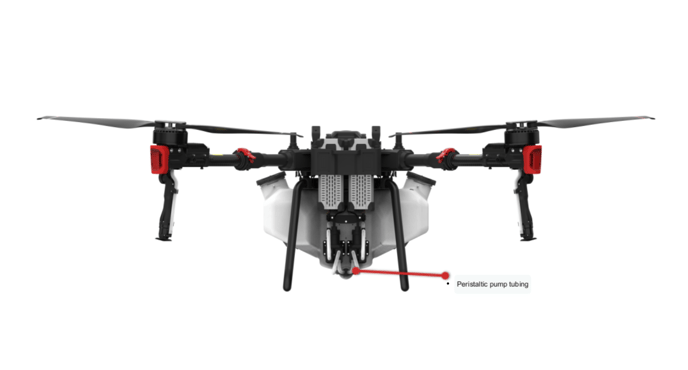

Inspection maintenance spraying is to allow the spray system to perform optimally, to make peristaltic pump flow more accurate during operation, and to make the tubing more durable, and the following parts can be inspected.

|Spray system

Check the cable ties at each interface of the drug tube, and if there is any looseness, use the cable ties to fasten; If the drug tube is worn, it needs to be wrapped with "cloth tape" for protection; If there is cracking and aging, the drug tube needs to be replaced in time.

|Ruibo system

Due to the corrosiveness of fertilizer, long-term non-maintenance of the spreader can make the spreader corrosion wear easy jamming, twister damage, after each spreading operation, it is necessary to clean the residual fertilizer on the material box, twister and throwing plate, which can effectively prevent fertilizer from corroding spare parts and extend the service life of the Rui sow system..png?width=688&height=342&name=Untitled%20design%20(1).png)

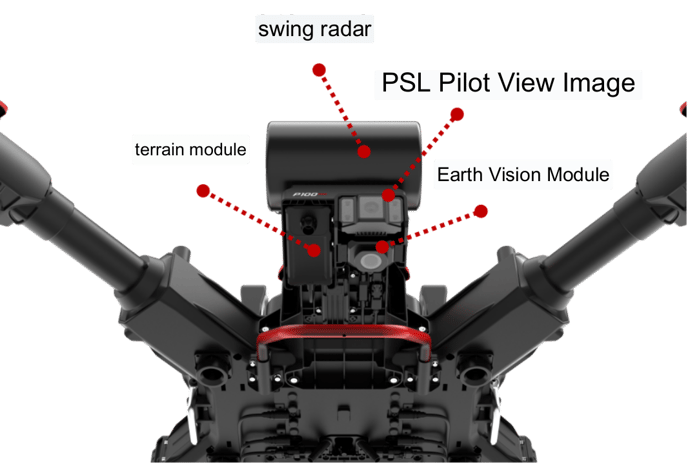

4. Clean and inspect the sensor system

The perception system is like a human eye, in ultra-long-distance operation or uneven terrain, can allow the equipment to ensure flight safety at the fastest operating speed, such as foreign objects on the swinging radar, may cause radar misjudgment to affect the efficiency of operation, you can use a lens cloth to wipe the lens of imitation ground radar, ground vision and PSL perspective image to ensure that it is clean and free of foreign objects.

Phase 3: Maintenance project with <>,<> mu of work

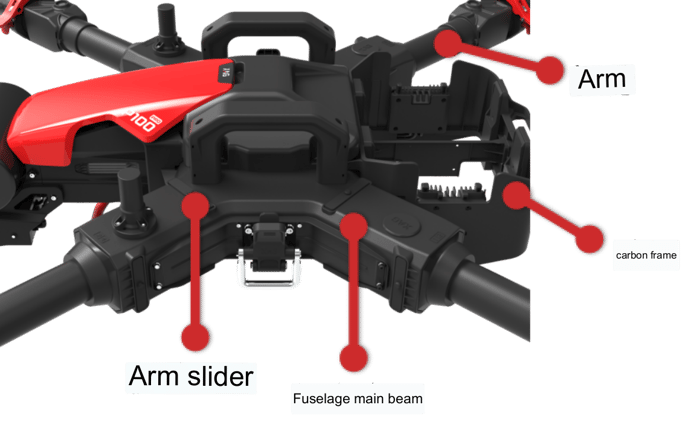

1. Check the fuselage

In the process of long-term operation, due to the slight vibration of the body will lead to loose the body spiral, in the transportation process will often collide with other items or press the body, will lead to deformation or damage to the structure, flying again after the abnormality will increase the safety risk of operation, need to be maintained as soon as possible, the main steps:

The first step is to visually check whether the arm slider, tripod, main beam, and carbon frame are deformed, and if there is deformation or breakage, it needs to be replaced in time.

The second step is to check whether the fixing screws of the fuselage are loose, slippery, rusted or broken, and replace the screws if any.

The third step is to remove the hood and check whether the cable at the flight controller is worn or broken, whether the interface is faulty, and if so, the cable needs to be replaced.

The fourth step is to check whether the fixing screws of the execution system, tripod and material box are loose, slippery, rusted or broken, and replace the screws if any.

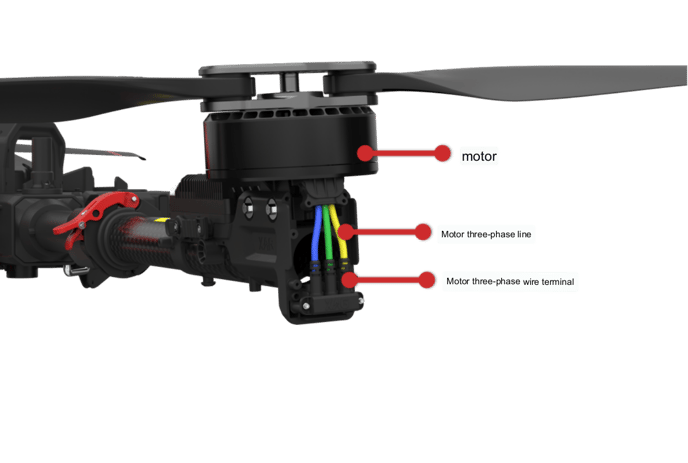

2. Check the powertrain

Motor

Motor is the most critical component of the entire power system, the loss degree of the motor directly determines the power output and load, such as maintenance is not in place during high-speed flight the motor will stop rotating, resulting in the equipment will directly explode, generally the degree of damage is more serious, in order to avoid this phenomenon need to do a good job of maintenance, the main steps:

(1) Turn the motor, if there is abnormal noise and stuck, use a soft brush to clean the foreign matter or dust remaining on the enameled wire of the motor; Visually inspect the enameled wire of the motor, if it turns black, the motor needs to be replaced;

(2) Check the motor three-phase wire and terminals, if there is wear, you need to wrap the motor three-phase wire with "acetate tape" for <> layers to ensure that the wire skin is not exposed; If there is a break, the motor with damaged wiring or terminals needs to be replaced.

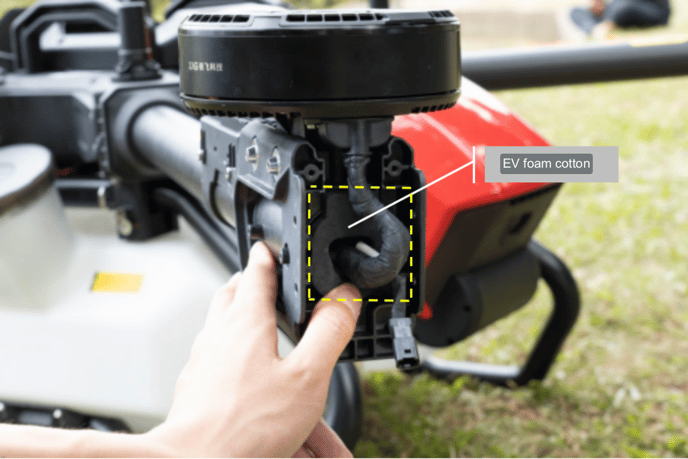

(3) Remove the spray lamp, check the EV foam, and replenish the foam if it is missing;

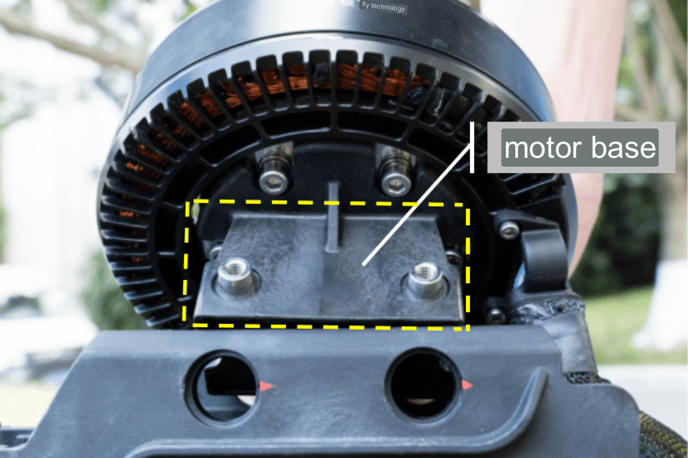

|Motor base

(1) Shake the motor, check the motor base, and tighten the screws if it is loose; If there is a break, it needs to be replaced;

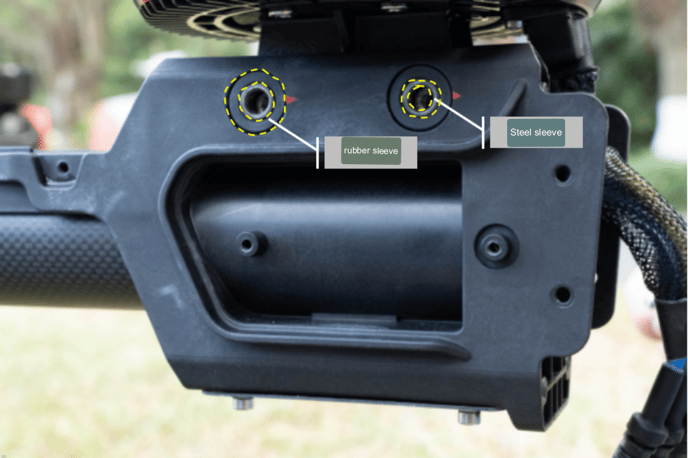

(2) Unscrew the fixing screw of the motor base, visually and touch check the steel sleeve, if there is a crack, replace the steel sleeve, rubber sleeve, screw and motor base;

ESC:

Whether the maintenance of ESC equipment is in place also directly determines whether the power system can play the best work efficiency, in the process of daily operation, wear will lead to ESC discharge current is too small, motor speed is low, load is low, low operating efficiency, ESC overheating will lead to stop current output during flight, resulting in motor no power to produce explosion, generally the bomber is more serious.

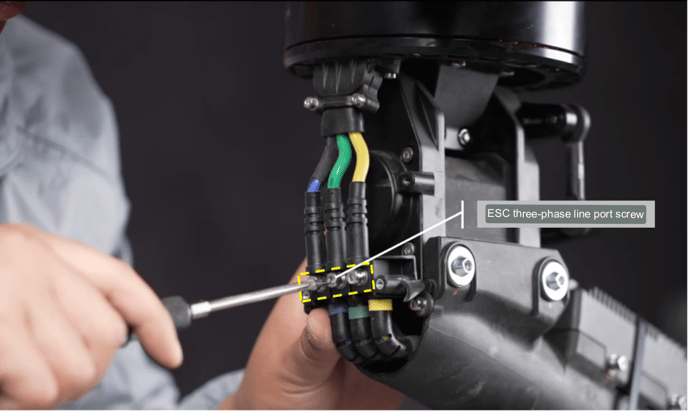

(2) Check the ESC three-phase wire and terminal, if there is wear, you need to wrap the motor three-phase wire with "acetate tape" for <> layers to ensure that the wire skin is not exposed; If there is a break, the motor with damaged wiring or terminals needs to be replaced.

(3) If you use <> models, you need to check the three-phase wire port screws, and tighten

them in time if they are loose.

3. Check the peristaltic pump tubing of the Jet system

The peristaltic pump determines whether the spraying amount of the spraying system is accurate, and in the long-term work, it is inevitable that there will be wear and blockage, and it needs to be dealt with in time, the specific operation steps are as follows:

(1) Remove the peristaltic pump, observe the peristaltic pump tube, if there is blockage, aging or damage, it is necessary to clean up the foreign matter in the pipe and replace the peristaltic pump tube, and calibration test is required after installation;

(2) Check the degree of lubrication between the peristaltic pump tube and the "synchronous disk", and if the lubrication is poor, apply "Vaseline".

Phase 5: Maintenance project with <>,<> acres of operation

1. Check the powertrain

Whether the propeller gasket is complete and wear-free determines that the propeller will have a large vibration during high-speed rotation, resulting in excessive wear of the gasket, and the greater the vibration of the equipment during flight, the serious will lead to the explosion, the specific operation steps are as follows:

The first step is to check the paddle gasket, if there is crushing and wear, it needs to be replaced in time;

.png?width=688&height=371&name=Untitled%20design%20(2).png)

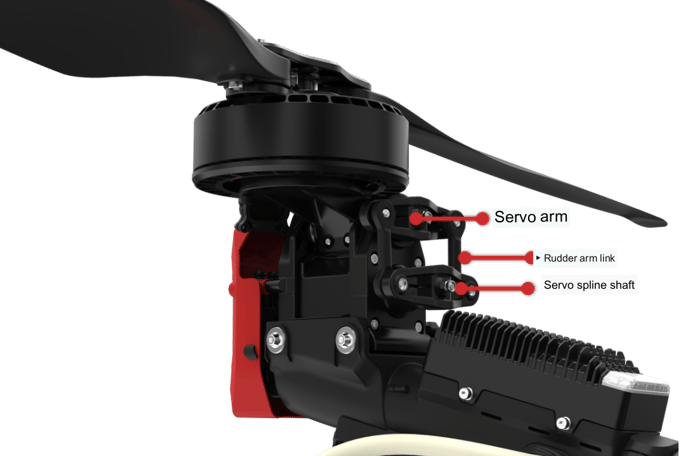

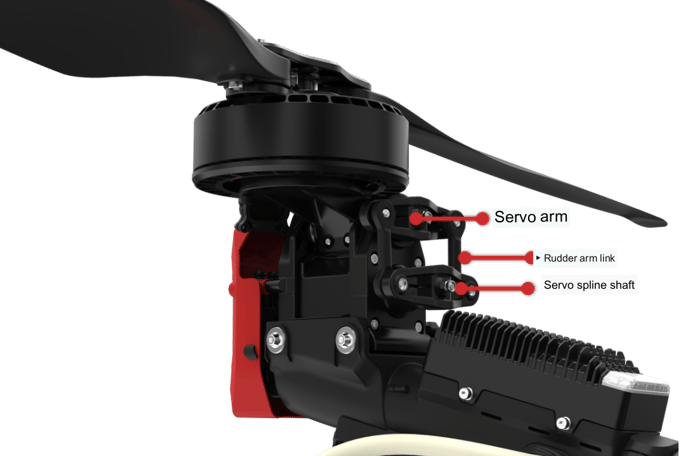

The second step is to check the swing arm and connecting rod of the servo, tighten the screws if they are loose, and replace them if they are broken;

2. Check the power system

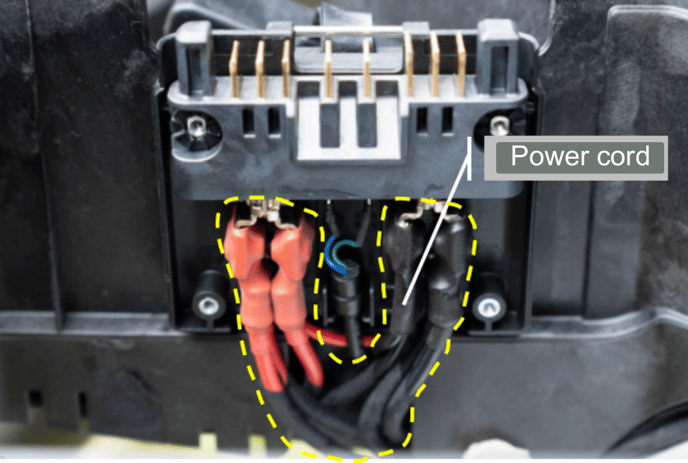

The operating environment is complex, long-term contact with the battery, if there are other foreign objects in the battery discharge process due to the increase in resistance, will burn the black tail plug, long time not cleaned, will make the tail plug and the battery can not be repeated contact, or lead to unstable discharge current, easy to produce explosives, the specific maintenance steps are as follows:

In the first step, use a cotton swab dipped in 75% alcohol, clean the metal piece of the tail insert, if there are traces of ignition, the tail insert needs to be replaced;

In the second step, shake the tail plug by hand, if there is no room for activity, it needs to be removed and reassembled;

The third step is to remove the tail socket shell, check the tail plug power cord, if it is damaged, burned or broken, the tail plug needs to be replaced.

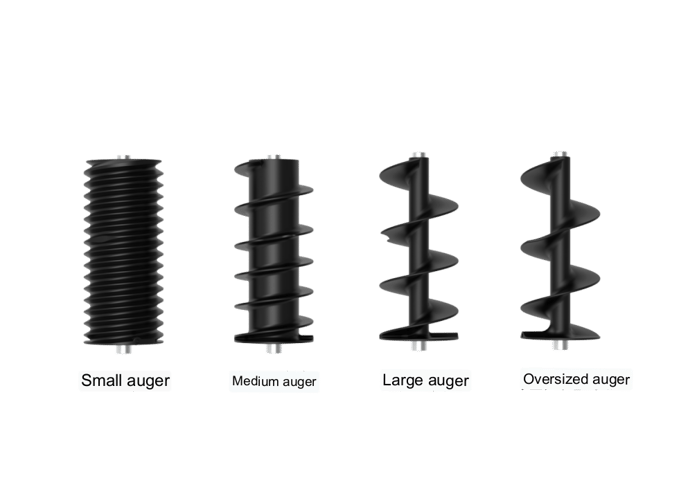

3. Check the Broadcast system

Long-term spreading operation, the use of irregular hard fertilizer, will make the dragon wear, after wear common abnormal situation is "auger jamming, auger leakage, leftovers" and other phenomena, in order to avoid this situation, we need regular maintenance, the specific maintenance steps are as follows:

Remove the throwing disc and twister and clean it to check for wear and tear, and replace them if they are larger than 2 mm

4. Check the perception system

4. Check the perception system

Flight controller commonly known as unmanned aircraft brain, unmanned aircraft so the instructions are converted by the flight controller, including positioning system, anti-ground radar and other modules, such as flight controller fixing screws loose, will lead to the phenomenon of "dancing" during the flight, equipment is high and low, at this time it may be that the flight controller fixing screws are loose, in order to avoid this situation, the following maintenance steps need to be done:

The first step is to check the mounting bracket of the flight controller, and if it is not secure, tighten the fixing screws; Replace if there is deformation;

The second step is to check the fixed mechanism of the front radar, if there is deformation and need to replace it immediately, please make sure that the connecting wire is on the left side after replacement;

Stage 1: Maintenance projects with operations of <>,<> mu and above

The arm is the equipment "arm" In the process of long-term operation, the arm hoop will also be repeatedly opened and closed, in the operation of 1,<> mu also need to check whether the arm hoop screw is compact and not loose, such as a long time without maintenance serious will lead to "fracture" during the flight The general bomb situation is more serious, in order to avoid similar situations, the following maintenance process needs to be operated:

The first step is to check the arm, whether there is cracking and damage, whether the arm hoop is complete and not loose, if there is any abnormality, please go to the service station immediately to replace;

The second step is to remove the hood and check the cable at the flight controller, if there is wear, breakage, interface failure, the cable needs to be replaced.

The third step is to power up the unmanned aircraft (do not fly), manually shake the motor, if the servo spline shaft has a false position, be sure to go to the service station to deal with it;

The fourth step is to check the spray plate, if there are broken teeth and damage, it needs to be replaced in time;

The above are the items that need to be maintained after each operation of the unmanned aircraft and the operation reaches 3,5 mu, 1,<> mu, and <>,<> mu.

.png?height=120&name=Pegasus%20Robotics%20Logo%20-%20Portait%20(2).png)